It was a solo brew day today as today is my last day off before I go on interviews and then when I return it's back to the real world and rotations. Due to the size of this beer (22 lbs of grain + 7 gallons of water to strike with) I had to mash on our work bench in the garage. Normally, we mash on the ground, then lift the cooler up to the bench to lauter the sweet wort. However, since I wouldnt have been able to lift the cooler, I did everything up on top today. The only issue was adding the crushed grain to the water as I couldnt pour and stir like I normally do. Instead, they grain was just added in sections, about 25% at a time. As you can see from the picture we about maxed out the mash tun with the grain/water.

I switched up the boil length this time and increased it to 90 min (from 60). I am hoping that by adding some boil time, we'll increase the efficiency by allowing us to use more water initially. However, I ended up with about a half gallon more wort than I anticipated, so the gravity was a little lower than last year (1090 comapred to 1099 last year). If I would have been able to boil off that extra 0.5 gallon, we would have been almost identical to last year's gravity. This year should clock in around 9.5% alcohol, which is still good enough for a winter-warmer ale.

Normally to save time, while the boil is going I will empty out the mash tun and then clean the cooler. I put the spent grain into a garbage bag and then go inside to clean the cooler. I normally leave the dogs outside while I'm gone because they are usually pretty well behaved. When I came back down the garage I found Bailey with her head in the back eating some grain! This is even after they each got a small portion to munch on.

We also put the black lager into secondary and sampled it. It finished at 1015, for 5.25% alcohol; the sample also tasted very good. The color was "browner" than I thought, although it looks black while in the carboy. We'll secondary it for about 2 weeks to clear it up a bit more and then we'll keg it and put it into the fridge to lager it properly. I'll be very excited to try this one in a few months.

We'll be bottling the Dubbel soon as well. I'm looking forward to trying it to see what difference the homemade candi sugar will make. Even though the sugar was pretty dark, it didnt lend as much color to the beer as we wanted, and it is therefore much lighter than we would like. But right now I'm more concerned about the flavor of the beer as color is pretty easy to adjust in the future. After that we'll be bottling the barleywine and then brewing our last beer using the Cali Lager yeast. After the steam beer we will need to make our Russian Imperial Stout for next winter, and then finally, I will be able to brew the Double Pale Ale with our neighbor again. We bought the hops for that beer at the same time as the Black IPA, so everytime I open the freezer I'm reminded about that beer.

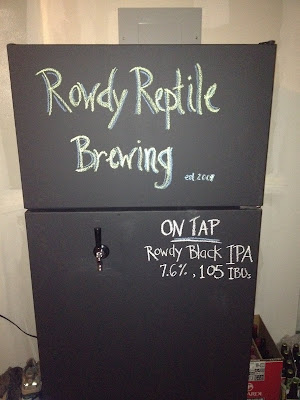

As for the Black IPA, I think it is finally carbonated and it tastes pretty good. Elise and I have been noticing a "soapy" mouthfeel and subtle flavor to the beer though. This could be due to the brewing water or potentially carbonic acid. When people try to carbonate kegs very quickly you can get a build up of carbonic acid intially, but it dissipates after a week or two. If they flavor goes away, it will likely be the carbonic acid, but since it's a mouthfeel sensation as well, I think it is most likely the high amount of carbonates in the water. I've ranted about that before, so I'll leave it alone for now.