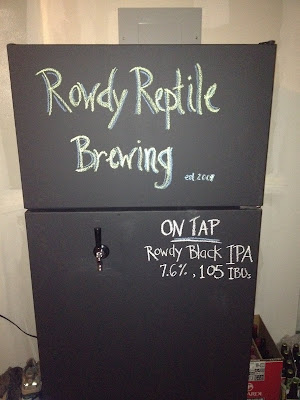

We finally received the new faucet from the online retailer and were able to successfully pseudo-carbonate the Black IPA. It's not completely carbonated yet, but it will hopefully be completed in about 7 days as the keg equilibrates with the CO2 tank at our desired carbonation level.

I had originally bought 4.5' beverage lines, but after talking with the people at the homebrew store, I found out that that length of line would be too short. By being too short, we wouldnt provide enough resistance to offset the pressure in the keg, aka: Foam City. However, I went and bought an 8' line and it is pouring very nicely now.

Another thing to consider was the fact that we are living at 5414 ft of elevation. To get our desired carbonation levels, we have to adjust our regulator pressure up 1 PSI for every 2000 ft. This was another reason why we needed longer lines to properly balance the system.

We are really enjoying the beer so far. It's hop aroma/flavor are very good with lots of citrus notes and the bitterness is nice and firm as well. Right now, as it is still undercarbonated, it is feeling like a hand-pulled beer by being slightly creamier, but as the carbonation increases, this will fade and hopefully the hoppiness will shine a bit more.

Over time we are going to slowly start accumulating more kegs with the goal of having 3 beers on tap at a time. Right now we could easily fit 3 kegs in the fridge (with the CO2 tank outside the fridge), but we could likely fit more if we build a shelf in the bottom to allow us to use the space in the back of the fridge where a hump is. If we have 3 beers on tap at at time I think we would need to have at least 5 kegs. The other 2 would be conditioning/carbonating while the others were being served. By having the other 2 kegs "on deck" we wouldnt have to wait long in between blowing one keg and drinking the next one in line. To have 3 kegs going we'll need 3 more kegs, 2 more faucet/shanks, and we'll have to get either a multiline regulator or a splitter to supply CO2 to all of the kegs. The splitter would be the cheapest and would simply split the CO2 into as many lines as we need. The only issue would be that all 3 kegs would be on the same CO2 pressure and therefore have the same level of carbonation. This would work for about 75% of the beers we brew, as they are mostly of the American persuasion. However, if we wanted to have an English- of Belgian-style ale on tap we would need to alter their levels of carbonation separately as they require higher and lower levels than American ales. This is where a multiregulator system would allow us to dial in each keg separately to our desired carbonation. This is more expensive than the simple splitters, but provides much more control.

We plan on brewing a Brown Ale tomorrow that will hopefully be ready to keg in 4 weeks to allow us something to have when the Black IPA kicks. I will be interested to see how fast it takes us to finish the keg compared to other beers. I see us using our 9 oz taster glasses for the keg more often than pint glasses, but with the ease of just pulling a pint I think we'll drink that beer more often than other ones. Hopefully it will last long enough to get the brown ready so we dont have an empty tap.

Below are a couple of screen shots of the types of regulators/splitters we would need to have 3 kegs going at once.

No comments:

Post a Comment